Precast Concrete Building Plans: Essential Aspects for Optimal Design and Construction

Precast concrete buildings offer numerous advantages in terms of construction speed, durability, and cost-effectiveness. To ensure a successful precast concrete building project, meticulous planning and detailed blueprints are paramount. This article delves into the essential aspects of precast concrete building plans, providing valuable insights for architects, engineers, and contractors.

1. Planning and Coordination

Precast concrete building plans require comprehensive coordination between the architect, engineer, and precaster. The design team must establish clear communication channels to seamlessly integrate the precast elements into the overall building design. This involves determining the optimal precast unit sizes, connections, and transportation logistics.

2. Precast Element Design

Precast concrete elements are designed to withstand specific loads and conditions. The engineer must carefully calculate the element dimensions, reinforcement requirements, and connection details. The design should consider the unit's weight, handling, and erection procedures. Moreover, architects should select finishes and textures that are compatible with the precast concrete's characteristics.

3. Connection Details

Connections between precast concrete elements play a crucial role in the building's overall integrity. Engineers must design secure and efficient connections that ensure load transfer and prevent premature failure. Common connection types include cast-in-place joints, grouted connections, and mechanical fasteners. The choice of connection depends on the element's weight, load conditions, and architectural requirements.

4. Erection Planning

The erection plan outlines the sequence and methods for assembling the precast concrete elements on-site. This plan should consider the crane capacities, site logistics, and safety protocols. Detailed instructions for handling, lifting, and connecting the precast units minimize the risk of damage and ensure a successful installation process.

5. Quality Control and Inspection

Quality control is essential throughout the precast concrete manufacturing, delivery, and erection process. Precasters must adhere to industry standards and specifications to ensure the production of high-quality elements. Regular inspections are conducted to verify the elements meet design requirements and ensure their structural integrity before installation.

Precast concrete building plans are a cornerstone of successful precast concrete construction projects. By considering these essential aspects, design teams can create detailed plans that optimize building performance, ensure project efficiency, and achieve the intended design intent.

Plan Views Of A Precast Concrete Building Model Scientific Diagram

Construction Plans Of The Three Floor Precast Building Scientific Diagram

A Construction Drawings For Walls And Floor Of Precast Concrete House Scientific Diagram

Concrete Plant Precast Technology

Cool Energy Efficient Concrete House Plans Houseplans Blog Com

Floor Plans Of The Apartment Building Constructed With Pre Cast Scientific Diagram

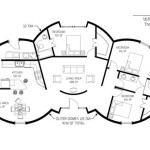

Cool Energy Efficient Concrete House Plans Houseplans Blog Com

Precast Concrete Modular Structure Dwg Plan For Autocad Designs Cad

Modern Facade Design For A Lightweight Precast Concrete House From Charming Haus

Cool Energy Efficient Concrete House Plans Houseplans Blog Com